METALL-400 Large metallographic sample cutting machine

I. Instruction

This machine is automatically controlled by Siemens PLC, driven by the control system, stepping motor motion control, X,Y,Z direction automatic and accurate control, cutting can be changed according to the material hardness feed speed, to achieve the fastest cutting effect, with very high reliability and control ability.1. The touch screen displays various cutting data, which is more accurate, clear at a glance, precise positioning, and better positioning of the cutting workpiece during cutting.

2. Chopping cutting, flat pushing cutting, sweeping cutting and three functional cutting methods. When cutting, the cutting speed can be adjusted according to the hardness of the material to achieve the purpose of fast cutting the workpiece. When cutting steel solid cylinder, different cutting methods can be selected.

3. In order to facilitate the cleaning of the cutting room and the safety of the spindle motor, we have adopted electromechanical separation; the cutting room motor is protected by waterproof isolation. The large observation window is installed on the safety protection door of the cutting room, so that the user can easily observe the whole cutting process of the sample; the LED lighting lamp is installed in the cutting room to realize the effective lighting of the whole cutting room area; the brightness and clarity in the working room are increased;

4. The design is more humanized, using the principle of ergonomics. The biggest feature: low noise, easy to operate, beautiful appearance, safe to use. Is one of the necessary equipment for laboratory sample preparation.

Body form; vertical. It is mainly composed of upper part (safety cover), middle part (frame), right sliding door, side opening door, lower frame (electrical box), fixture, flushing water gun and cooling water tank (independent).

This cutting machine, designed for large-volume cutting of large workpieces, makes it easier to maintain machine parts and handle large workpieces. Sliding doors and hinged doors give you more space and unlimited access, making it easier to load large workpieces in the right place. The workpiece can also be fed into the cutting chamber from above, front, left, 3.

The work area is fully enclosed with a transparent protective cover for observation during cutting. Equipped with cooling water to provide storage coolant, avoid using tap water as coolant. After the cutting work is completed, rinse the faucet with the left side, rinse the indoor garbage and close the safety door.

II.Main technical parameter

Cutting method:Chop cutting, flat push cutting, sweep cutting

Cutting speed:0.01-1mm/s(adjustment step 0.01)

Reset mode:Automatic

Control system:Siemens PLC 7”touch LCD screen

Spindle rotation speed:2800rpm

Max. stroke:Z axle 130mm;Y axle 200mm;X axle 100mm

Working table size:128*320mm 180*320mm

Max. diameter:φ 130mm

Cutting blade:400*4*32mm

Cutting Power:4KW

Voltage:380V/ 50Hz

Dimension:1350*1100*1750mm(L×W×H)

III.Electric control specification

1.Electronic control principle

Cutting equipment for automatic equipment, using Siemens PLC, with 7 inch LCD touch screen. System power input: three-phase four-wire AC380V 50Hz.

IV.Function introduction

Automatic operation is divided into Y-axis direction, X-axis direction, Z-axis direction using stepper motor control, touch screen operation.

The panel is equipped with a touch screen, and button switches for start, stop, and emergency stop. After the equipment is powered on, turn on the main power switch, press the start button, the system will be powered on, and press the stop button, the system will be powered off. The emergency stop button is the emergency stop button of the system. Press the system to stop the action.

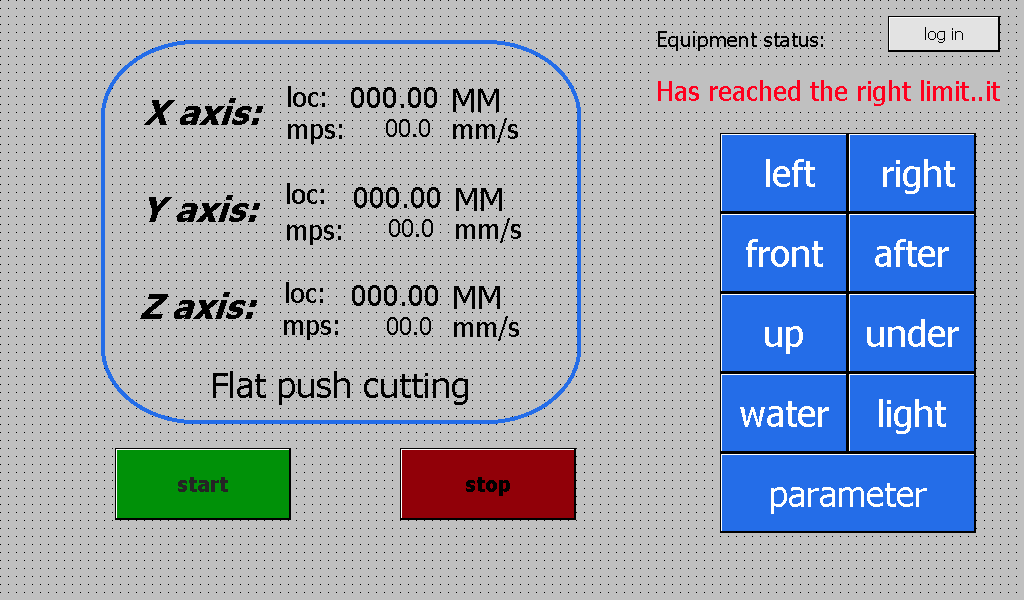

The operation screen is as follows

1) Main interface

Main screen from top to bottom respectively display: X.Y.Z position display, automatic start.

Stop button, cutting mode display, direction button, parameter setting button.

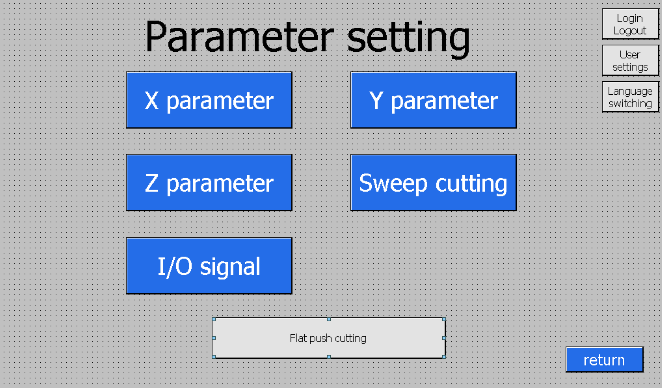

2)Parameter setting screen

Click parameter setting from the main screen to enter 5 sub-screens: X-axis parameter setting, Y-axis parameter setting, Z-axis parameter setting, scanning and cutting parameter setting, I/O signal debugging and cutting mode conversion button

Click the 5 parameter setting in the parameter setting to enter the respective setting screen. The cutting mode button switches respectively: horizontal push test cutting, sweep cutting and chop cutting;

Flat push cutting is completed by Y-axis movement, which is controlled by cutting distance and cutting speed in Y-axis parameter setting. Opening can also change cutting mode (direct cutting, intermittent cutting, advance and retreat cutting) in Y-axis parameter setting.

Sweep cutting is to set parameters in the parameter setting in the sweep parameter setting.

Sweep cutting is completed by Z-axis movement, which is controlled by cutting distance and cutting speed in Y-axis parameter setting. Opening can also change cutting mode (direct cutting, intermittent cutting, advance and retreat cutting) in Y-axis parameter setting.

3)Parameter setting screen

① Manual speed setting: Set the manual adjustment speed on the touch screen, and adjust the value according to the need to control the speed of manual movement,

②Automatic speed setting: set the automatic cutting speed, according to the material, hardness and cutting thickness of different workpieces. Set different cutting speeds.

③ Cutting distance setting: Set according to different cutting modes. This setting is the setting value of reciprocating cutting mode. The setting value of non-backward distance is used in conjunction with the setting value of cutting distance should be greater than the setting value of backward distance.

④ back distance setting: set according to different cutting mode setting, this setting is the setting value of reciprocating cutting mode, the set back distance. This setting is less than the cut distance setting.

⑤ Cutting stroke setting: Set according to the cutting length of different workpieces, the length of the workpiece to be cut, the set value should be greater than the actual cutting size of the workpiece.

⑥ cutting pause time setting: set the intermittent pause time, this setting is the pause time after setting the cutting distance set value, and cut again after reaching the set time, thus realizing the setting of intermittent cutting mode.

⑦ Y-axis current position: display the current position value. If it needs to be set to zero, press the position reset button to return the value to zero.

Z-axis screen is similar to Y-axis

4)X Display-operation picture

① Manual speed setting: Set the manual adjustment speed on the left and right of the screen, and adjust it according to different needs.

Section manual speed setpoint

② Current position: display the current position value, if you need to return to zero, you need to press the position to reset the number of keys

The value will return to zero.

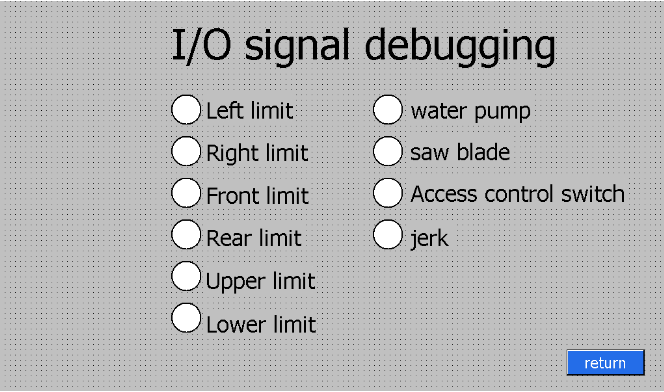

5)I/O signal debugging interface

The status display screen shows the status of the system. When the system fails, you can enter this screen to check the system's failure.

Display the function of the equipment and equipment parameters and precautions.

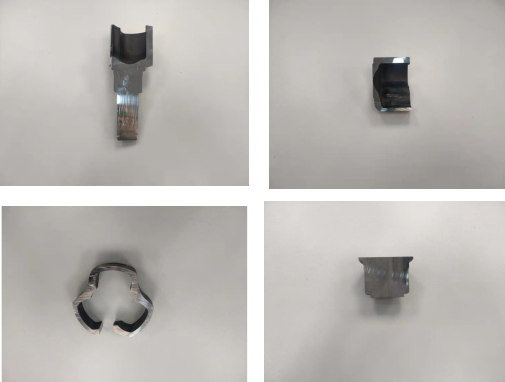

Cutting effect picture

Packing list

| Name | Model | Unit | Quantity | Note |

| Main machine | set | 1 | ||

| Water tank | (含水泵) | set | 1 | |

| Cutting blade | 400×4×32mm | pc | 2 | |

| Outlet pipe | pc | 1 | ||

| Inlet pipe | pc | 1 | ||

| Buckle ring | pc | 2 | ||

| Spanner | pc | 3 | ||

| Manual | copy | 1 | ||

| Certificate | copy | 1 | ||

| Packing list | copy | 1 |