8MHBS-3000 Electronic Digital Brinell Hardness Tester

8MHBS-3000-4 Electronic Digital Brinell Hardness Tester can display the data of each operation process and test results on the LTD touch screen, and the data of the test results can be output through the printer. This machine is suitable for all kinds of production and processing enterprises, colleges and universities, laboratories of scientific research machinery.

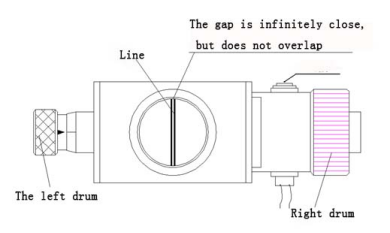

The test process of the machine is displayed on the LCD touch screen, the indentation can be directly measured on the instrument through the micrometer eyepiece, and the diameter of the indentation can be displayed on the LCD touch screen display screen, and the electronic force is applied.

Determination of the Brinell hardness of ferrous metals, non-ferrous metals and bearing alloy materials, with a wide range of applications, suitable for precise measurement of parallel planes, and stable and reliable measurement of curved surfaces.

Main Specifications:

Name

Specification

Test force

31.25kgf,62.5kgf,100kgf,125kgf,187.5kgf;306.45N,612.9N,980.7N,1266N,1839N

Convertible ruler

HRA、HRB、HRC、HRD、HRF、HV、HK、HBW、HR15N、HR30N、HR45N、HR15T、HR30T、HR45T

Measuring range

8~650HBW

Data output

Built-in printer

Maximum allowable height of the test piece

280mm

Indenter diameter(mm)

Φ2.5

Objective lens

1X、2X

The distance from the center of the indenter to the machine wall

150mm

Power supply

AC220V,50Hz

Hardness reading

Digital display touch screen LCD to read hardness value

Implementation standard

ISO 6506,ASTM E10-12,JIS Z2243,GB/T 231.2

Dimensions

1000×595×350mm

Weight

150Kg

The metal Brinell hardness test system uses a certain diameter of cemented carbide balls, presses into the surface of the material to be tested with a specified test force (Figure 1a). After holding for a specified time, the test force is removed, and the indentation on the surface of the sample is measured (Figure 1b). diameter, to calculate the Brinell hardness, and calculate the:

HBW=0.102 x 2F/πD(D- )

)

in the formula:F--------Test force N;

D-------Ball diameter mm;

d--------Indentation average diameter mm;

HBW---Brinell hardness measured with a carbide ball indenter.

For example: 216HBW10/3000/10, when the hardness of 216 is measured with a cemented carbide ball with a diameter of 10mm and a test force of 29.42KN (3000kgf) for 10 seconds, its Brinell hardness is represented by the symbol HBW, and so on.

Product advantages

01 The data of each operation process and test results can be displayed on the large LCD screen. During operation, just measure the indentation and press the eyepiece button, the hardness value can be automatically calculated and displayed on the screen.

02 The data of the experimental results can be output through the printer.

03 There are 14 hardness conversion scales that can be converted.

Packing List:

Name

Specification

Unit

Quantity

Note

Brinell hardness tester

Set

1

Big flat workbench

Dia. 240mm

Pc

1

Small flat workbench

Dia.80mm

Pc

1

V-shaped table

Pc

2

Carbide indenter

Φ1Φ2.5、Φ5、Φ10

Pc

4

Standard Brinell hardness block

200±50HBW 10/3000

Pc

1

Standard Brinell hardness block

100±25HBW 10/1000

Pc

1

Accessory box

Pc

1

Dust cover

Pc

1

Manual

Sheet

1

Power cable

Pc

1

Certificate of Qualification

Sheet

1